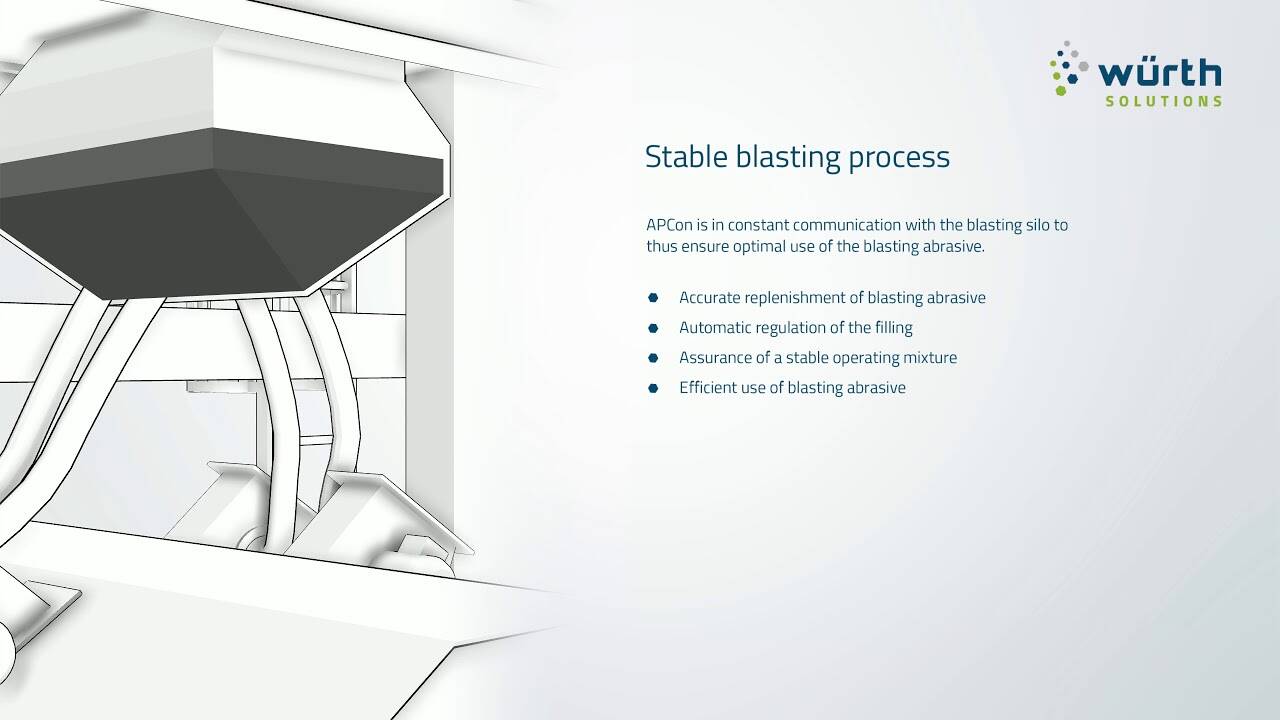

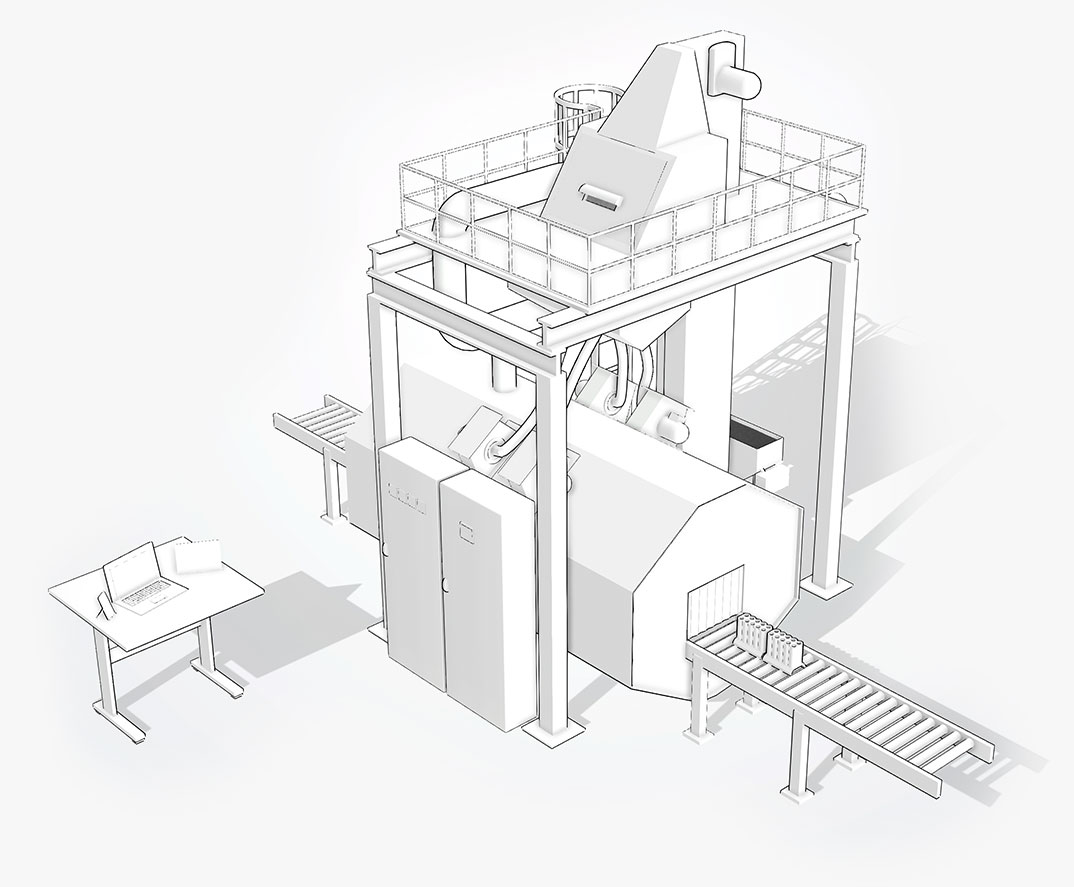

With APCon, we offer you a process optimisation system with which you can monitor and control your blasting system online. In future, you will have both important key figures for consumption, and complete documentation, real time analyses and much more available at a glance. So, by continual optimisation, you can increase your productivity and make the blasting process very economical.

Documentation

Precise monitoring of the blasting process at all times, incl. recording the data

Precise monitoring of the blasting process at all times, incl. recording the data

Energy efficiency

Revealing savings potential and therefore long-term optimisation of the energy consumption

Revealing savings potential and therefore long-term optimisation of the energy consumption

Economic viability

Optimisation of use of blasting abrasive amongst other things, for economically optimised operation of the blasting system

Optimisation of use of blasting abrasive amongst other things, for economically optimised operation of the blasting system

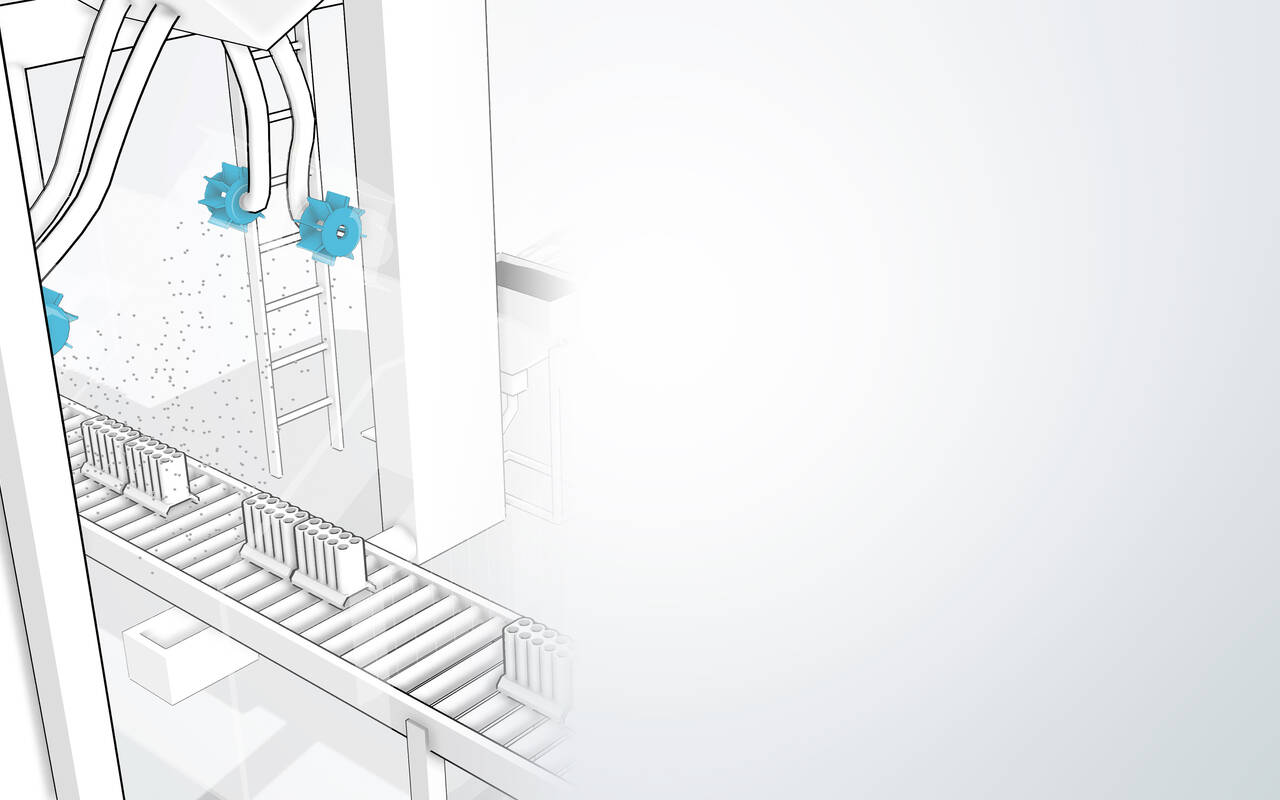

Sensors:

Modern sensors monitor the processes of the blasting system and record numerous data

Software:

The APCon software analyses and processes the incoming data, to highlight inefficient processes and identify optimisation potential

Knowledge & service:

Thanks to years of experience, Würth recognises economic weak points and helps to evaluate the data and continually optimise the process

Modern sensors monitor the processes of the blasting system and record numerous data

Software:

The APCon software analyses and processes the incoming data, to highlight inefficient processes and identify optimisation potential

Knowledge & service:

Thanks to years of experience, Würth recognises economic weak points and helps to evaluate the data and continually optimise the process

Start your digital future with us

Your contact person

Dietmar Marx

Tel. +49 (0) 71 36 98 98 22

Mobil +49 (0) 160 2139 847

marx(at)eisenwerk-wuerth.de